Bulcs Holding Americas, LLC

BULCS Holdings, a leading distributor of indoor air quality, drying system and building restoration solutions across Australia and the Asia Pacific is now expanding to the USA and Canada.

ENVIRONMENTAL SOCIAL GOVERNANCE

The restoration industry contributes a relatively small percentage to the global carbon footprint. However, a study in the UK estimated that flood restoration activities could generate around 12 tons of CO2 emissions per incident. This figure comes from an analysis of the carbon footprint associated with various flood restoration processes, including the use of drying equipment, dehumidifiers, transportation of materials, and waste disposal.

At BULCS, we lead with industry experience, bringing forward technology that improves sustainability and reduces waste. Not only does our technology contribute to the preservation of our planet, but it also positions our industry at the forefront of advancements. We no longer need to be known as the industry of disaster and waste. We are leading the transformation of restoration into a powerful means of combating global impact and creating a better living environment for everyone.

TECHNOLOGY

Restoration data logging and continuous monitoring involve systematically recording and tracking restoration processes, ensuring real-time oversight and accuracy to enhance operational efficiency, compliance, and long-term sustainability.

Providing the latest technology, state-of-the-art monitoring systems, and data logging, BULCS leads trends in technology to deliver a sustainable and efficient way to work.

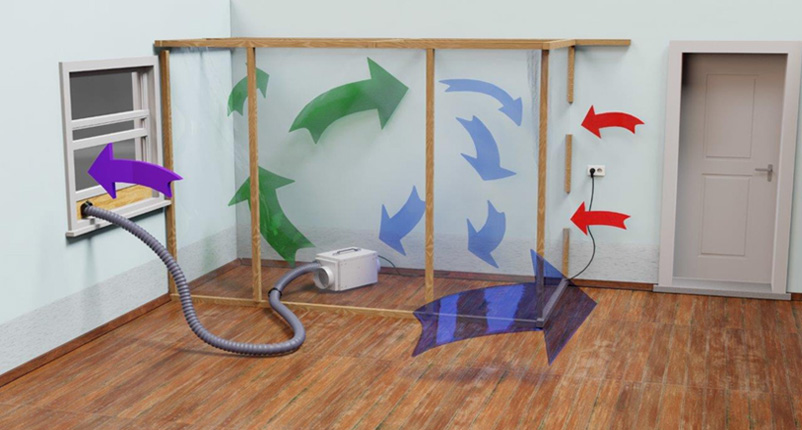

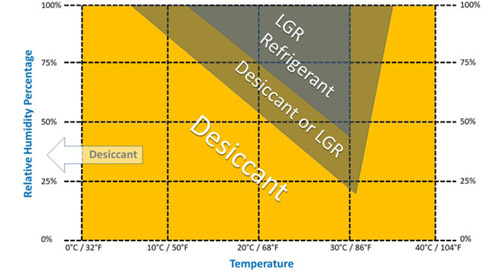

Use the right dehumidifier for the environment you are working in and also the temperature the unit will be mostly working in to get the best drying performance.

Level of Dryness Needed

A normal home will be comfortable to live in at around 50-70% relative humidity. Moreover, that will depend very much on the preference of the home owner. All dehumidifiers have a tolerance level regarding their accuracy.

Thus, can vary by 5-15%. Scales should be taken as relative. A lot depends on the size of the room, what is in the room being dried and the air refresh rate from outside the room bringing in outside humidity. The last factor is time.

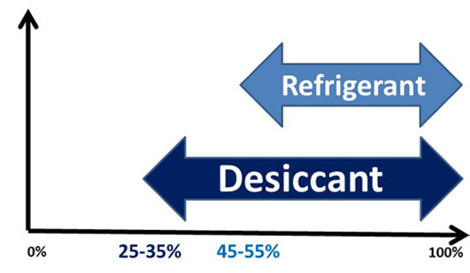

Low Grain Refrigerant or Desiccant?

Desiccant dehumidifiers are ideal for low temperature applications. At higher temperatures, especially above 95ºF, additional strain is placed on the compressor.

In these instances, a low grain refrigerant is a more effective solution.

EPD170 LGR

Refrigerant Dehumidifier

.gif)

EPD100 LGR

Refrigerant Dehumidifier

.gif)

EPD50-RESTO

Desiccant

.gif)

EPD150 DryFan

Desiccant

.gif)

EPD200 DryFan

Desiccant

-

Office

11506 Robertson Road Manassas, VA. 20109

-

Email